Sheet metal parts are found almost everywhere and PREMIUM MACHINING can help you quickly and accurately make your enclosures, brackets, assemblies, weldments, cabinets, housings and other sheet metal parts and prototypes.

Our MOQ is one and offer options for low/mid volumes.This ranges from high-quality bending, cutting, punching, and welding with top-notch machines. The result is producing durable parts with vast materials skillfully manufactured by our technicians with substantial experience that will meet your exact requirements.We will show you why Sheet Metal Fabrication services will ultimately benefit you.

Common sheet metals include steel, stainless steel, aluminum, zinc, and copper, and these materials usually come in gauges between 0.006 and 0.25 inches (0.015 and 0.635 centimeters) thick.

How It Works

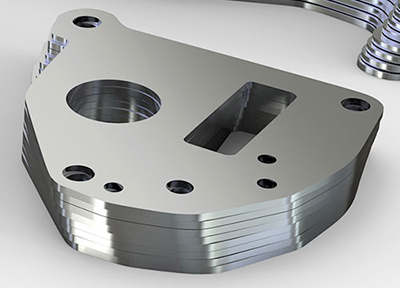

Sheet metal encompasses a wide range of processes to manipulate and shape sheets of metal into the required geometry.Premium Machining use bending, laser cutting, punches, welding and other processes to manufacture your sheet metal parts and prototypes.

Cutting

Laser cutting is typically the first step in the manufacturing process.It involves using specialized tools, such as shears or laser cutters, to cut the metal sheet into the desired shape.laser cutting is the preferred method for achieving high-quality cuts. Laser cutting enables a high degree of precision (+/- 0.1 mm) and is time-efficient.

The cutting process is complex and depends on the type of material. Also, the preferred final product plays a crucial role in the selection of the cutting process. The main cutting processes include:

● Mechanical

cutting

● Laser cutting

● Punching

● Shearing

● Waterjet cutting

Bending can create a wide range of shapes and angles, from simple bends to

complex shapes that require multiple bends.

Bending

The bending process is known as CNC folding and is a practice that can be

completed using a variety of machines. For example, a manual press brake or

automated panel bending machine. The machine forms the metal part by clamping

the sheet metal and applying pressure to maintain the desired

curvature.

Punching

Punching is a valuable technique for a wide range of metal sheets. During the punching process, fabricators press the punch through the metal sheet, creating a hole in the desired shape and size. And position the die underneath the metal sheet to collect the scrap material created from the hole. In addition to creating holes, punching can also make indentations in the metal sheet, and create features such as dimples or countersinks.

Welding

Welding is an essential process in sheet metal fabrication that involves joining metal pieces together to create a single part.

There are various welding techniques available,

1.Metal inert gas (MIG) welding: A typically fast welding option that is better for thicker materials.

2.Tungsten inert gas (TIG) welding: Offers greater control and precision than MIG. Best for thinner materials. You may also see it referred to as gas tungsten arc welding (GTAW).

3.Robotic MIG welding: This is an automated version of more traditional MIG welding.

4.Spot welding: This follows an electrical resistance welding process.

Assembly

Assembling is the final step of the metal fabrication process that enables the creation of complex metal structures and components. By using the right methods and techniques, sheet metal fabricators can create high-quality products that meet all required specifications and standards.

Advantages of Sheet Metal

● Quick and inexpensive

Used for

Prototypes and low volume production, medical and communications products, housings and enclosures. Premium Machining makes many types of customized metal, plastic, aluminum enclosure . Enclosures used to protect printed circuit boards, electrical installations or equipment. Our enclosures are mainly used in the following fields such as power electronics, communications, industrial control, medical electronics, security electronics, consumer electronics, computers and automotive electronics. Tailored to your specifications and to any desired volume.

Premium's engineers think with you and advise you on material selection, material thickness, etc. We also offer the possibility to design solutions. Provide us any specifications, design drawing and we can assist you with your design. Premium can save you valuable time and costs.

Contact: Amanda

Phone: +86 138 2885 2656

Tel: +86 138 2885 2656

Add: 2nd Floor NO.39,Zhen'An West Road,Chang An Town, Factory 2:No. 49, 1st Street, Changtang 3rd Industrial Zone, Dalang Town,Dong Guan,China 523878