What Is CNC Turning?

The increased complexity of products requires complex components of varying sizes and shapes. In the past, this requirement would have introduced several problems, such as increased costs as well as delays in producing the hardware. The development of computer numerical control (CNC), however, avoided that possibility. Now, it provides industries with a quick and reliable tool for machining custom parts with precision via CNC turning, which removes unnecessary material to form the desired shape.

Applications for CNC Turning Centers

In a variety of industries, CNC turning centers are useful for creating the following products:

Prototypes

Spacers

Manifolds

Fittings

Shafts

Bushings

And more

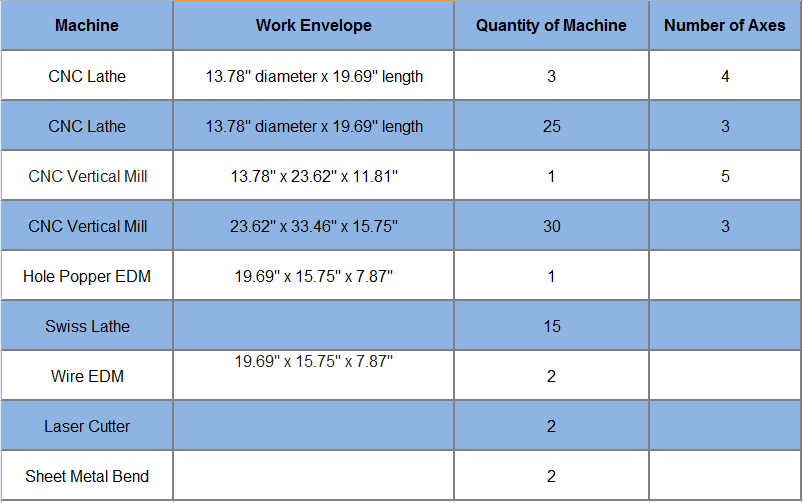

PREMIUM Machine List:

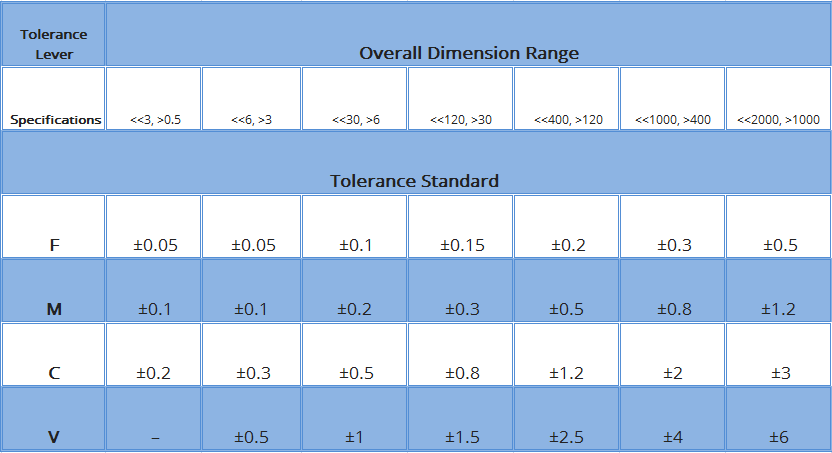

Standard Tolerances

With high precision milling & turning machines, we are able to catch super tight tolerance for prototype machining & production. Parts will be made accordingly to our customers’ specification. If 2D drawings are not available, you can also indicate with ISO 2678. The table below is the ISO 2678 standard for your reference.

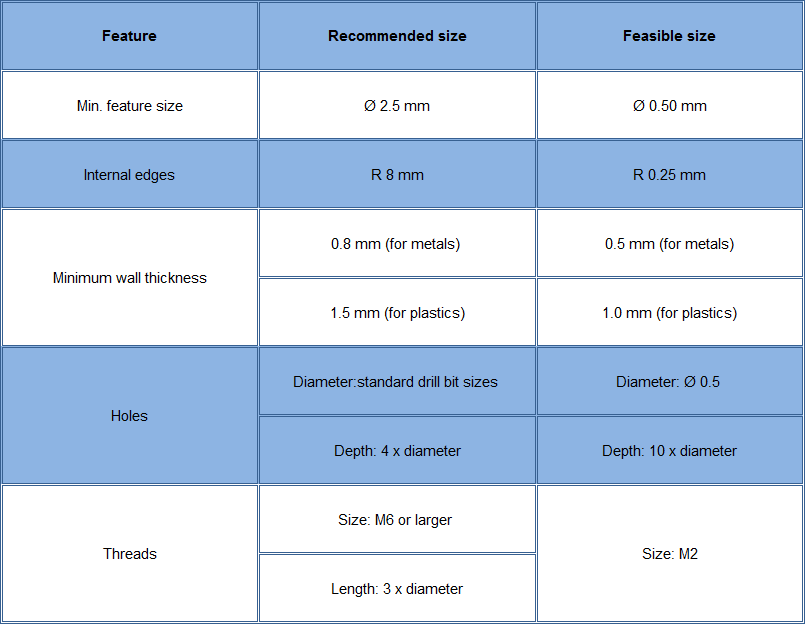

CNC turning design guidelines

The table below summarizes the recommended and technically feasible values for the most common features encountered in CNC machined parts.

See more about our CNC Turning Serivics.

Contact: Amanda

Phone: +86 138 2885 2656

Tel: +86 138 2885 2656

Add: 2nd Floor NO.39,Zhen'An West Road,Chang An Town, Factory 2:No. 49, 1st Street, Changtang 3rd Industrial Zone, Dalang Town,Dong Guan,China 523878